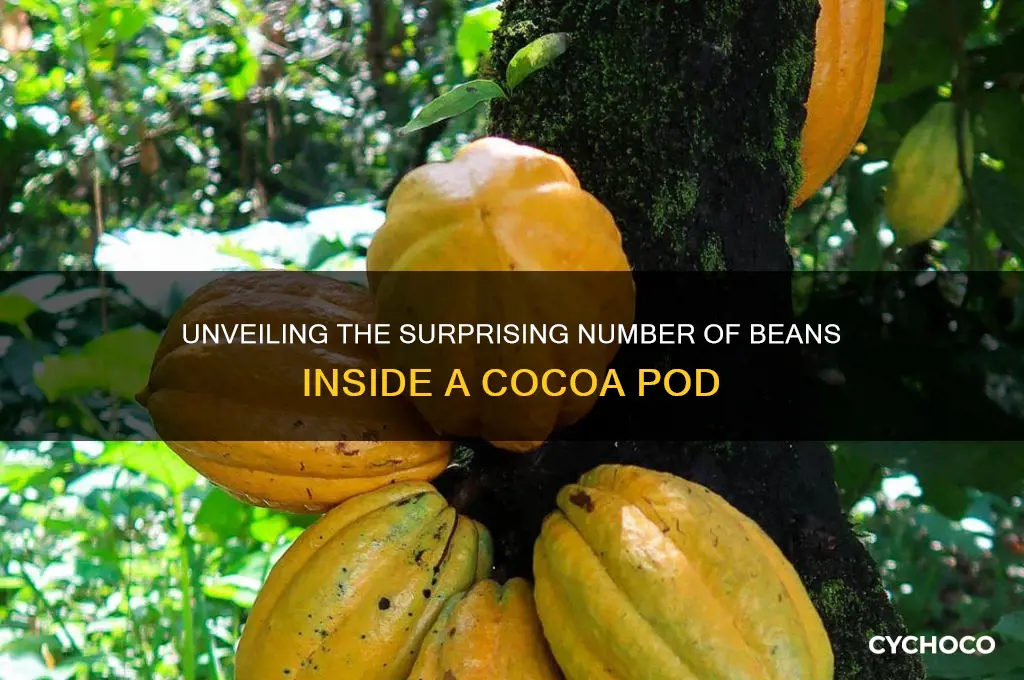

Cocoa pods, the fruit of the cacao tree, are a fascinating subject for chocolate enthusiasts and botanists alike, especially when considering the number of beans they contain. Typically, a single cocoa pod houses between 20 to 60 beans, depending on the variety and growing conditions. These beans, nestled in a sweet, pulpy interior, are the key ingredient in chocolate production. The pod’s size and shape can vary, but its contents are consistently crucial to the global chocolate industry. Understanding how many beans are in a pod highlights the labor-intensive process of chocolate making, as it takes approximately 400 beans to produce just one pound of chocolate.

What You'll Learn

Average number of beans per pod

The average cocoa pod houses 30 to 40 beans, but this number isn’t set in stone. Factors like cocoa variety, growing conditions, and pod size play a significant role. For instance, the Criollo variety, prized for its delicate flavor, tends to produce smaller pods with fewer beans (around 20-30), while the more robust Forastero variety, which makes up the majority of global cocoa production, yields larger pods with 40-50 beans. Understanding these variations is crucial for farmers and chocolatiers alike, as bean quantity directly impacts yield and flavor profiles.

To estimate bean count without cutting open a pod, consider its size and weight. A mature pod typically weighs between 300 to 500 grams, with larger pods generally containing more beans. However, this method is imprecise, as pod density can vary. For a more accurate assessment, carefully slice open the pod lengthwise and count the beans in one of the five longitudinal rows. Multiply this number by five, then adjust for any irregularities in the remaining rows. This hands-on approach is both educational and practical, offering a tangible connection to the cocoa-making process.

From a practical standpoint, knowing the average bean count per pod helps farmers optimize their harvests. For example, if a tree produces 50 pods annually and each pod contains 40 beans, that’s 2,000 beans per tree per year. Given that it takes approximately 400 beans to make one pound of chocolate, a single tree could theoretically contribute to five pounds of chocolate annually. However, factors like disease, weather, and soil quality often reduce actual yields, underscoring the importance of sustainable farming practices to maximize productivity.

Comparatively, the bean-to-pod ratio highlights the labor-intensive nature of cocoa production. Unlike crops like corn or wheat, where yields are measured in bushels or tons, cocoa is harvested pod by pod, and each pod must be split open manually to extract the beans. This process, combined with the relatively low bean count per pod, explains why cocoa farming is both time-consuming and resource-intensive. Innovations in harvesting tools and techniques could alleviate some of this burden, but for now, the average number of beans per pod remains a critical metric for assessing efficiency and profitability in the cocoa industry.

Discover the Best Sources to Find Quality Cocoa Beans Globally

You may want to see also

Variations by cocoa tree species

The number of beans in a cocoa pod varies significantly across species, reflecting each tree’s genetic makeup and environmental adaptations. For instance, *Theobroma cacao*, the most widely cultivated species, typically produces pods containing 20 to 60 beans. In contrast, *Theobroma bicolor*, a lesser-known species, yields pods with fewer but larger beans, often ranging from 10 to 20. This variation is not merely a curiosity—it directly impacts yield calculations and farming strategies, as growers must account for species-specific productivity when planning plantations.

Consider the *Criollo* variety, prized for its delicate flavor but notorious for low pod yields. A single *Criollo* pod may contain only 15 to 25 beans, compared to the hardier *Forastero* species, which averages 30 to 50 beans per pod. This disparity highlights the trade-off between quality and quantity, a critical factor for farmers deciding which species to cultivate. For small-scale growers, maximizing bean count per pod may outweigh flavor considerations, while specialty chocolate producers often prioritize *Criollo* despite its lower yield.

Environmental factors further complicate species-specific bean counts. *Trinitario*, a hybrid of *Criollo* and *Forastero*, demonstrates how crossbreeding can mitigate vulnerabilities. Its pods typically contain 25 to 40 beans, offering a balance between flavor and resilience. However, even within the same species, pod size and bean count can fluctuate based on soil quality, rainfall, and temperature. Farmers in regions with consistent climates, such as Ghana or Côte d’Ivoire, may achieve higher bean counts per pod compared to those in more variable environments.

To optimize bean yield, growers should select species suited to their local conditions. For example, *Forastero* thrives in humid, low-altitude regions, making it ideal for West African farms. In contrast, *Criollo* requires well-drained soil and partial shade, conditions often found in Central America. Practical tips include spacing trees 3 to 4 meters apart to reduce competition and applying organic mulch to retain soil moisture. Regular pruning also encourages pod development, potentially increasing bean count by up to 20%.

Ultimately, understanding species-specific variations in bean count empowers farmers to make informed decisions. While *Forastero* dominates global production due to its high yields, niche markets reward the unique flavors of *Criollo* and *Trinitario*. By aligning species selection with environmental and market demands, growers can maximize both productivity and profitability, ensuring a sustainable future for cocoa cultivation.

Mastering Cocoa Bean Fermentation: A Step-by-Step Guide to Perfect Flavor

You may want to see also

Factors affecting bean count

The number of beans in a cocoa pod varies widely, influenced by factors that range from genetic traits to environmental conditions. Understanding these variables is crucial for farmers and chocolatiers alike, as bean count directly impacts yield and quality. Let’s dissect the key factors shaping this count, starting with the most foundational: the cocoa variety.

Variety Matters: The Genetic Blueprint

Cocoa pods come in three primary varieties: Forastero, Criollo, and Trinitario. Forastero, accounting for 80–90% of global production, typically yields pods with 30–40 beans. Criollo, prized for its delicate flavor, produces smaller pods containing 20–30 beans. Trinitario, a hybrid, falls in between with 25–35 beans per pod. These differences are hardwired into the plant’s DNA, meaning farmers must select varieties strategically to meet their yield goals. For instance, a farmer prioritizing quantity might opt for Forastero, while one focusing on premium flavor could choose Criollo, accepting a lower bean count for superior taste.

Environmental Stressors: The Invisible Hand

Climate and soil conditions act as silent regulators of bean count. Optimal cocoa growth requires temperatures between 21–32°C (70–90°F) and annual rainfall of 1,500–2,000 mm. Deviations from these ranges—such as droughts or excessive heat—can reduce pod size and bean development. For example, a study in Ghana found that pods exposed to prolonged dry spells contained 15% fewer beans than those in well-watered areas. Similarly, nutrient-poor soil lacking essential minerals like magnesium and potassium can stunt pod growth. Farmers can mitigate these effects by implementing shade systems to regulate temperature and using organic fertilizers to enrich soil, ensuring pods reach their full bean potential.

Pest and Disease Pressure: A Double-Edged Sword

Pests like the cocoa pod borer and diseases such as black pod rot can decimate bean counts. The pod borer, a moth larva, tunnels into pods, destroying up to 80% of beans in severe cases. Black pod rot, caused by fungi, can reduce bean viability by 30–50%. Integrated pest management (IPM) strategies, including biological controls like parasitic wasps and fungicides, are essential tools. For instance, applying fungicides at the first sign of infection can preserve bean integrity. However, overuse of chemicals can harm beneficial insects, underscoring the need for balanced, targeted interventions.

Farming Practices: The Human Element

Human intervention plays a pivotal role in maximizing bean count. Proper pruning ensures energy is directed toward pod development rather than unnecessary foliage. For example, removing lower branches allows more sunlight to reach developing pods, fostering healthier growth. Pollination management is equally critical, as cocoa relies on midges for pollination. Introducing midges or planting companion flowers like marigolds can enhance pollination rates, increasing pod fertility. Lastly, timely harvesting—ideally when pods are fully mature but not overripe—ensures beans are fully developed. A pod left too long on the tree may wither, reducing bean count and quality.

Takeaway: A Holistic Approach

Maximizing bean count requires a multifaceted strategy that addresses genetic, environmental, biological, and human factors. By selecting the right variety, managing environmental stressors, combating pests and diseases, and adopting best farming practices, producers can optimize pod yield. For instance, a farmer in Ivory Coast who switched to Trinitario and implemented IPM saw a 25% increase in beans per pod within two years. Such success stories highlight the tangible benefits of understanding and acting on these factors, turning cocoa cultivation into both an art and a science.

Best Places to Purchase Cocoa Bean Mulch for Your Garden

You may want to see also

Comparison to other fruit pods

A cocoa pod typically contains 20 to 60 beans, depending on the variety and growing conditions. This range, while specific to cocoa, invites comparison with other fruit pods to understand its uniqueness. Consider the vanilla orchid, whose pods (often misidentified as beans) house thousands of tiny seeds. Unlike cocoa, which relies on fermentation and roasting to develop flavor, vanilla’s value lies in its aromatic compounds, extracted through curing. This contrast highlights how pod structure and seed quantity align with each fruit’s culinary role.

Analyzing the jackfruit pod offers another perspective. A single jackfruit can weigh up to 100 pounds and contain hundreds of edible bulbs, each surrounding a seed. While cocoa pods prioritize seed (bean) quantity for chocolate production, jackfruit pods emphasize bulb volume for consumption. This difference underscores how evolutionary pressures shape fruit development: cocoa pods protect seeds for dispersal, while jackfruit pods attract animals with abundant, nutrient-rich flesh.

For practical comparison, examine the pomegranate, whose "pod" (aril-filled interior) contains 600 to 1,200 seeds. Unlike cocoa beans, which are processed into a single commodity (chocolate), pomegranate seeds are consumed directly, often for their antioxidant properties. This highlights how seed count correlates with end use: cocoa’s lower bean count reflects its labor-intensive transformation, while pomegranate’s high seed count supports its role as a ready-to-eat superfood.

Finally, the coconut pod exemplifies a different strategy. Each coconut contains a single, large seed (the edible endosperm) encased in a fibrous husk. While cocoa pods produce multiple beans for efficiency, the coconut invests in one seed, ensuring its survival during ocean dispersal. This comparison reveals how pod design—whether housing many small seeds or one large one—reflects ecological adaptation and human utilization. Understanding these differences enriches appreciation for cocoa’s place in the broader spectrum of fruit pods.

Mastering Home Fermentation: A Guide to Perfectly Fermented Cocoa Beans

You may want to see also

Harvesting and bean extraction process

The journey from cocoa pod to chocolate bar begins with harvesting, a delicate process that demands precision and care. Farmers typically wait 120 to 150 days after pollination before the pods are ready, identified by their vibrant colors—yellow, orange, or red, depending on the variety. Using a curved blade known as a *machete de cocoa*, harvesters carefully cut the pods from the tree to avoid damaging the delicate bark. This step is crucial, as injuries to the tree can reduce future yields. Once harvested, the pods are gathered and transported to a central location for bean extraction, a process that must occur within days to prevent fermentation or spoilage.

Extraction begins with splitting the pods open, revealing a white, pulpy interior that encases the beans. This task is often done by hand, using a machete or a specialized knife, to ensure the beans remain intact. The pulp and beans are then scooped out, typically into large wooden or plastic boxes. At this stage, the beans are still surrounded by a sweet, sticky pulp, which must be removed to prepare them for fermentation. Farmers often use their hands or simple tools to separate the beans, a labor-intensive process that requires skill and patience. The pulp, rich in sugars, plays a vital role in the next phase, as it fuels the fermentation process that develops the beans’ flavor.

Fermentation is a critical step in bean extraction, transforming bitter, tasteless seeds into the precursors of chocolate. The beans and pulp are placed in fermentation boxes or heaps, where naturally occurring yeasts and bacteria break down the sugars in the pulp. This process generates heat, raising the temperature of the beans and triggering chemical changes that develop their flavor and color. Fermentation typically lasts 2 to 7 days, depending on the desired flavor profile and local practices. Farmers must monitor the process closely, stirring the beans regularly to ensure even fermentation and prevent mold growth. Improper fermentation can ruin the batch, making this step both an art and a science.

After fermentation, the beans are spread out to dry, reducing their moisture content from about 60% to 7%. Drying methods vary by region, with some farmers using raised mats or tables in direct sunlight, while others rely on mechanical dryers. Proper drying is essential, as it prevents mold and ensures the beans can be stored without spoiling. Once dried, the beans are ready for bagging and transport to chocolate manufacturers. This entire process, from harvesting to drying, highlights the labor-intensive nature of cocoa production and the skill required to transform a pod into the foundation of one of the world’s most beloved treats.

Frequently asked questions

A single cocoa pod usually contains 20 to 60 cocoa beans, depending on the variety and growing conditions.

No, the number of beans in a cocoa pod varies by species, with Forastero pods typically having 20-40 beans and Criollo pods often containing 30-60 beans.

Approximately 400-500 cocoa beans are required to produce one standard-sized chocolate bar, depending on the recipe and cocoa content.

Yes, factors like soil quality, climate, and farming practices can influence pod size and bean count, potentially increasing or decreasing the number of beans per pod.